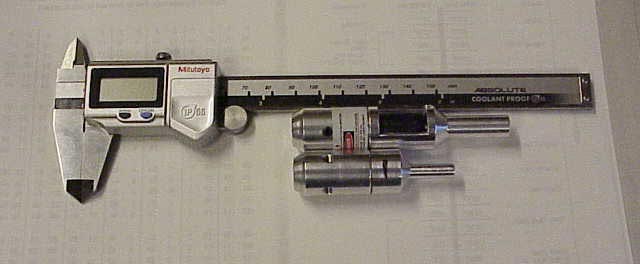

Product Overview

The Laser Center/Edge Finder ® is a new tool for your mill that will save setup time. For the new Home Shop Machinist, it will eliminate the frustrations and doubts of learning the century old Indirect Method with the conventional Edge Finders or Wiggler.

The Laser Center/Edge Finder ® is a Direct Method center or edge finder. Current Center/Edge Finders are Indirect Methods. Current Finders require the Mill operator to determine where the edge of the material is by imposing sufficient pressure on the finder to just slightly bump the material and then move over one-half the diameter of the edge finder to locate the true edge of the material. Another accepted method is a center/edge finder that has a spring loaded conical disc that kicks sideways when touching the edge of the material and the Mill operator then moves the mill table over one-half the diameter of the edge finder to locate the true edge of the material.

The mechanical/electrical center/edge finders function as the mechanical ones do except that instead of a spring loaded offset disc it utilizes electrical continuity to determine when the edge finder has contacted the material (not always useful on non-conducting material). The Mill operator hears an audible signal or a light comes on indicating contact has been made. The operator must still add half the diameter of the edge finder to determine the true edge of the material.

The Laser Center/Edge Finder ® only requires the Mill operator to move the table under the small Laser beam until the laser light shows a laser line down the side of the material. The Direct Method eliminates the most common mistake of forgetting to add half the diameter of the conventional center/edge finder to locate the true edge of the material.

If the Mill operator is attempting to position the Mill quill over a center punch mark on the material, the table is moved until the laser dot centers on the center of the punch mark. The operator then rotates the polarizer to make the dot smaller to make sure it is in the center of the center punch mark.